Products

Home > Products > Continuous Annealing Machine

Continuous Annealing Machine

- Features

- Specification

AN60 AN70 AN80 AN90 AN100 AN130 AN200 AN300 Transformer Capacity (KVA) 60 70 80 90 100 130 200 300 Wire Diameter (mm) 0.30~1.40 0.30~1.40 0.35~1.80 0.35~1.80 0.35~2.00 1.35~2.60 1.35~3.00 1.35~3.20 Max. Line Speed (M/min) 1800 1800 1600 1400 1200 1000 800 600 Output Voltage (V) 16~75 16~75 16~75 16~75 16~75 16~75 16~75 16~75 Primary Annealing Current (A) 160 160 210 210 250 280 300 350 Secondary Annealing Current (A) 1000 1000 1200 1200 1500 2000 2500 2750

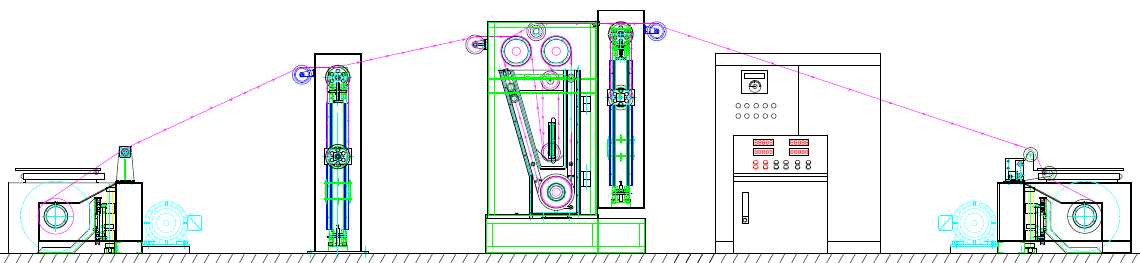

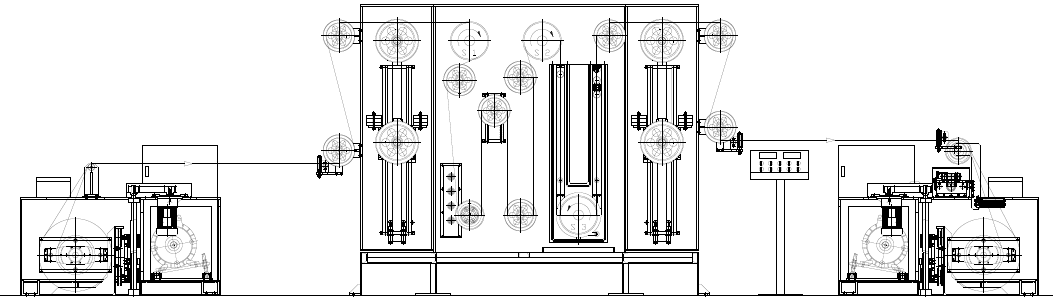

- Layout Drawing